Description

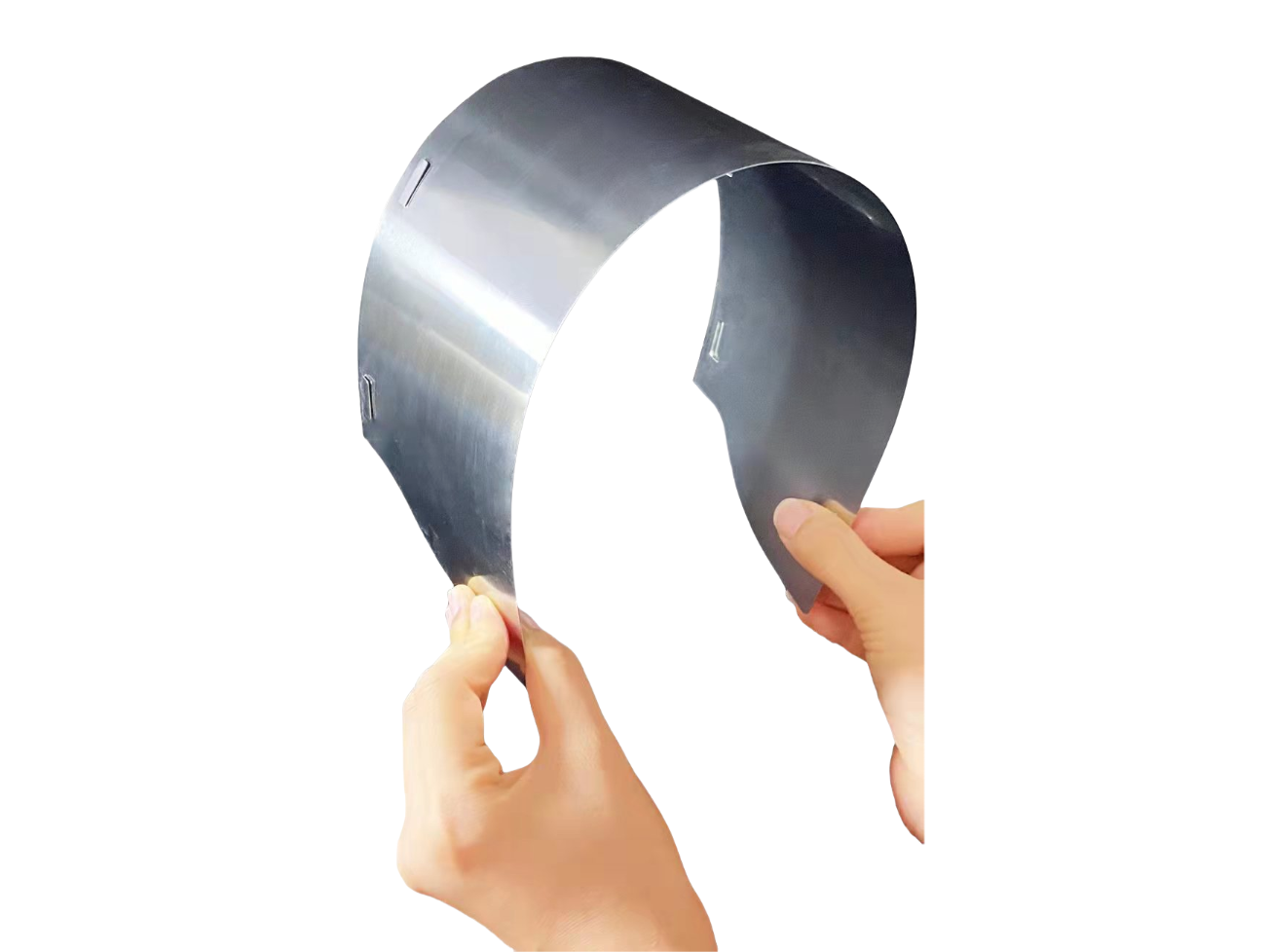

Replacement Blade Insert – The interchangeable blade is a key component of the skimming spatula tool. Crafted from high-grade stainless steel, these precision blades (available in 0.3mm and 0.5mm thicknesses) ensure sharp, smooth finishes on drywall, plaster, and other surfaces, reducing labor time and boosting efficiency.

The unique rounded edge design minimizes lap marks for flawless surface finishing.

-

High-density stainless steel with mirror polish—free of bubbles/pinholes.

-

Hardened treatment for durability (Vickers hardness: 480-530 HV).

-

High elasticity prevents deformation, extending service life.

-

Refined edge for safety: smooth, burr-free, and aesthetically crafted.

-

Corrosion-resistant (salt spray tested) and oxidation-proof.

-

Easy blade replacement: Remove end caps tool-free—no need to replace the entire tool.

Ideal as a spare blade or replaceable blade insert, this upgrade cuts costs without compromising performance.

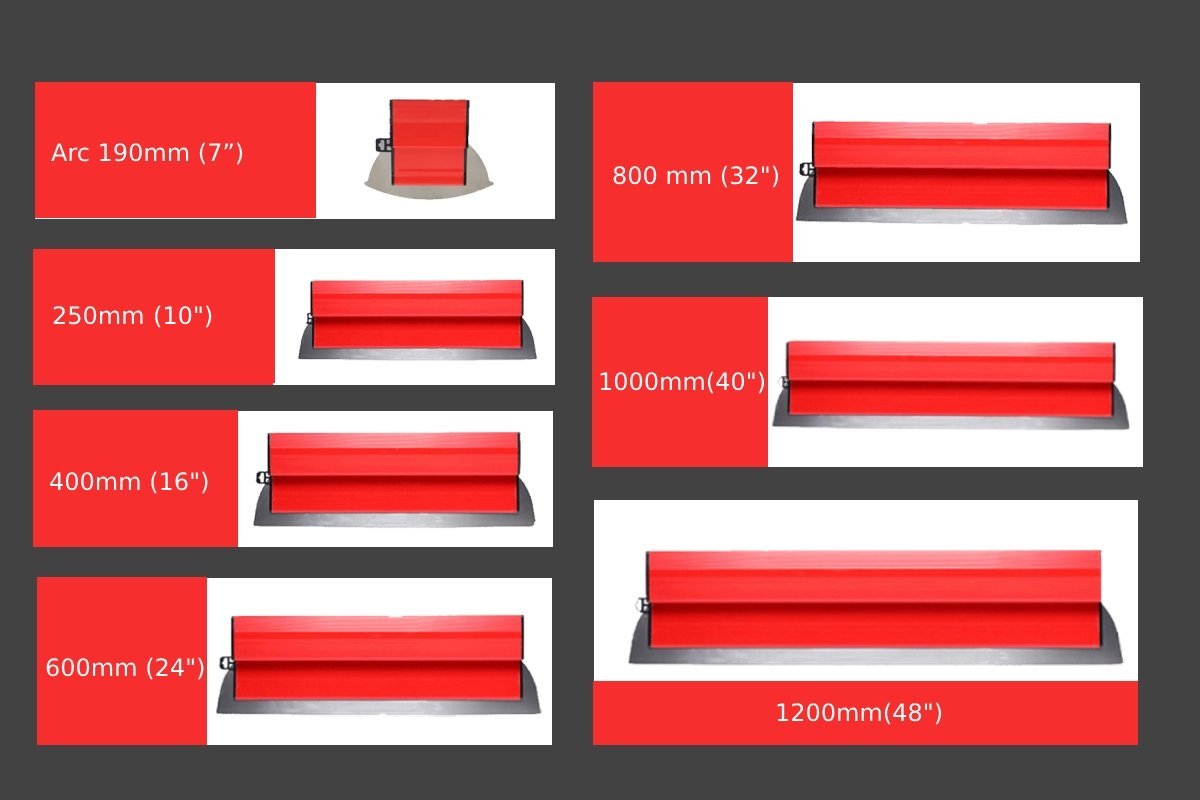

Skimming Blade Size Chart

These are our normal standard skimming blade tool sizes. We understand every project has unique requirements – that’s why we offer fully customizable blade sizes beyond our standard range. Whether you need specialized widths (from 15cm to 120cm), unique thicknesses (0.3mm/0.5mm), or project-specific lengths, our engineering team can create the perfect tool for your specific applications. Ideal for contractors working with unconventional surfaces or brands wanting exclusive product lines. Custom orders maintain the same premium stainless steel quality and precision engineering as our standard blades. Minimum order quantities apply. Contact us today to discuss your exact specifications and receive a personalized quote!

Our OEM/ODM Solutions

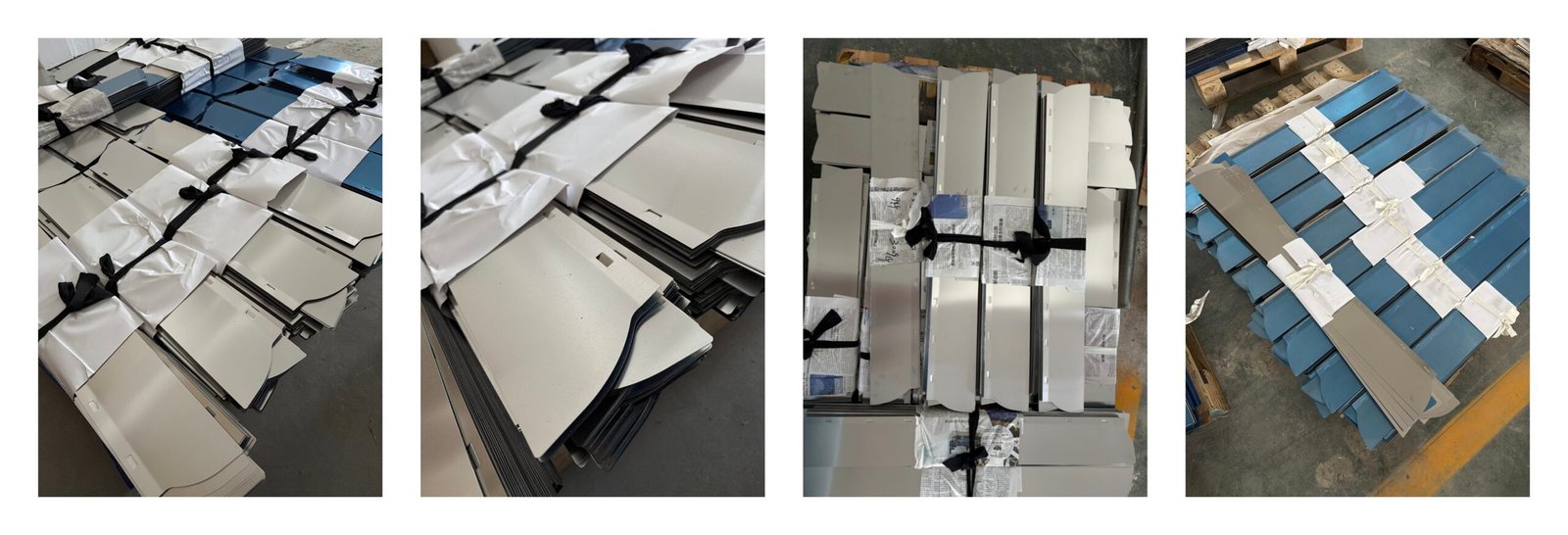

Our skimming blades stand out in the market with unmatched craftsmanship—visibly superior to competitors in finish and durability. Over 90% of clients become repeat buyers, a testament to our quality. With a 50,000-unit monthly capacity, we reliably meet bulk demands.

We offer full customization—colors, logos, packaging—backed by a dedicated team. Stay competitive with our regular new product kits, designed to match market trends. Currently serving 30+ countries, we provide 24/7 pre- and post-sales support to ensure seamless partnerships. Quality you can see, service you can trust.

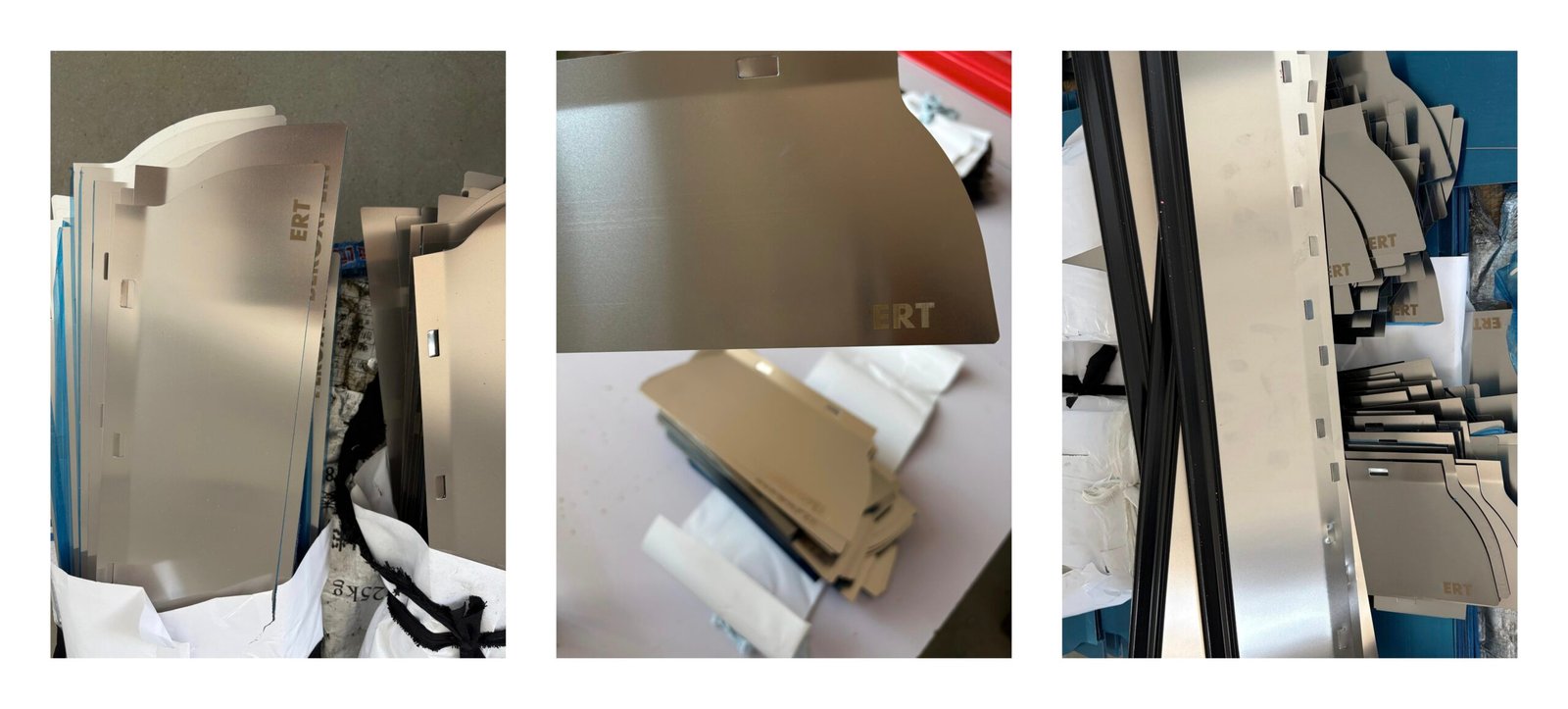

Our Custom Logo Options

If clients want skimming blades to be more branded and impressive, please choose our blade customization logo service. We offer Laser engrave for personalized logo to be placed on the skimming blade. It is engraved by our dedicated laser printing equipment according to the customer’s artwork design. The logo is accurate in size and never fades, which has excellent publicity effect among customers.

Currently we offer two kinds of stainless steel SS201 and SS301 and two thickness 0.3mm & 0.5mm for customers’ different requirement.

Why Choose Us

| Feature | Amal Skimming Spatula | Competing Products |

|---|---|---|

| Design Highlights | ||

| Blade Slot | Precision blade slot with minimal clearance, securing blade fixation (zero wobbling) and complete putty leakage prevention | The gap of the blade slot is large, the blade is loose, and there is a phenomenon of putty seeping in. |

| Housing Parts | ||

| Anti-ultraviolet Agent | Uses anti-ultraviolet agent from BASF of Germany, which is environmentally friendly, safe and reliable. | Uses common anti-ultraviolet agent |

| Temperature Resistance | Vicat softening temperature is above 85 degrees, no deformation at high temperature. | Vicat softening temperature is unstable, no guarantee of no deformation at high temperature. |

| Material Composition | Calcium carbonate content is controlled below 50%, excellent mechanical properties (such as tensile strength, bending modulus, etc.). | High calcium carbonate content, low tensile strength, easy to bend and crack. |

| Blade Spare Parts | ||

| Material Quality | Made of high-density stainless steel, mirror polished technology, no bubbles, no pinholes. | Ordinary stainless steel, with pores and uneven surface. |

| Hardness | After special hardening treatment, Vickers hardness (HV) reaches 480-530. | Vickers hardness (HV) between 280-330. |

| Elasticity | High elasticity, strong rebound without deformation during use, ensuring service life. | Weak rebound, easy to deform, short service life. |

| Blade Edge | The blade edge is refined, aesthetic, smooth and burr-free for safety. | Rough workmanship, burrs on the blade edge may cause injury. |

| Corrosion Resistance | Special process treatment, salt spray test, oxidation resistance, corrosion resistance. | Poor corrosion resistance. |

| Blade Protection Strip | Wide protective strip, protecting the blade and offering higher safety. | Narrow protective strip with low cost. Easy to fall off and poor performance. |

| End Cap | ABS hard material. Not easy to loosen, ensuring blade stability. | PP material. Low cost and easy to detach. |

Frequently Asked Questions

1.Can your spare blade insert be used with other brands of skimming spatulas?

Every brand skimming blade spatula tool has its own design and structure. There will be slight difference in size and shape. We recommend that customers only equip our skimming tools with this replacement blade insert.

2.What’s the minimum order quantity for your replacement blade insert?

For SS 201 blade insert 0.3/0.5mm, the MOQ is 500 pcs totally.

For SS 301 blade insert 0.3mm, the MOQ is 1500 pcs totally.

For SS 301 blade insert 0.5mm, the MOQ is 1500 pcs totally.

3.What’s the minimum order quantity for customizing Laser engraving logo?

For customizing Laser engraving logo, the MOQ is 300 pcs totally.

4. How long is your delivery time?

Delivery time varies by quantity:

Under 2000 pcs: 25-30 days

Over 2000 pcs: 30-40 day

5. How do you ensure product quality?

We follow strict quality control across 8 production lines and conduct inspections before shipment.

6. How is your packaging handled for wholesale or retail brands?

We offer standard bulk packaging or custom-designed retail boxes with your branding.

7. What’s the production capacity of your factory?

We can produce 30,000+ skimming blades per month, backed by 500k+ units in bulk storage.

8. Do you provide after-sales support?

Yes, we provide full support after purchase, including fast response on replacement or re-orders.

9. Can you help us develop exclusive product sets for our brand?

Definitely. We specialize in custom tool sets tailored to different market needs and brand styles.

10. What’s your standard payment method?

We accept T/T (bank transfer) as our standard payment term.