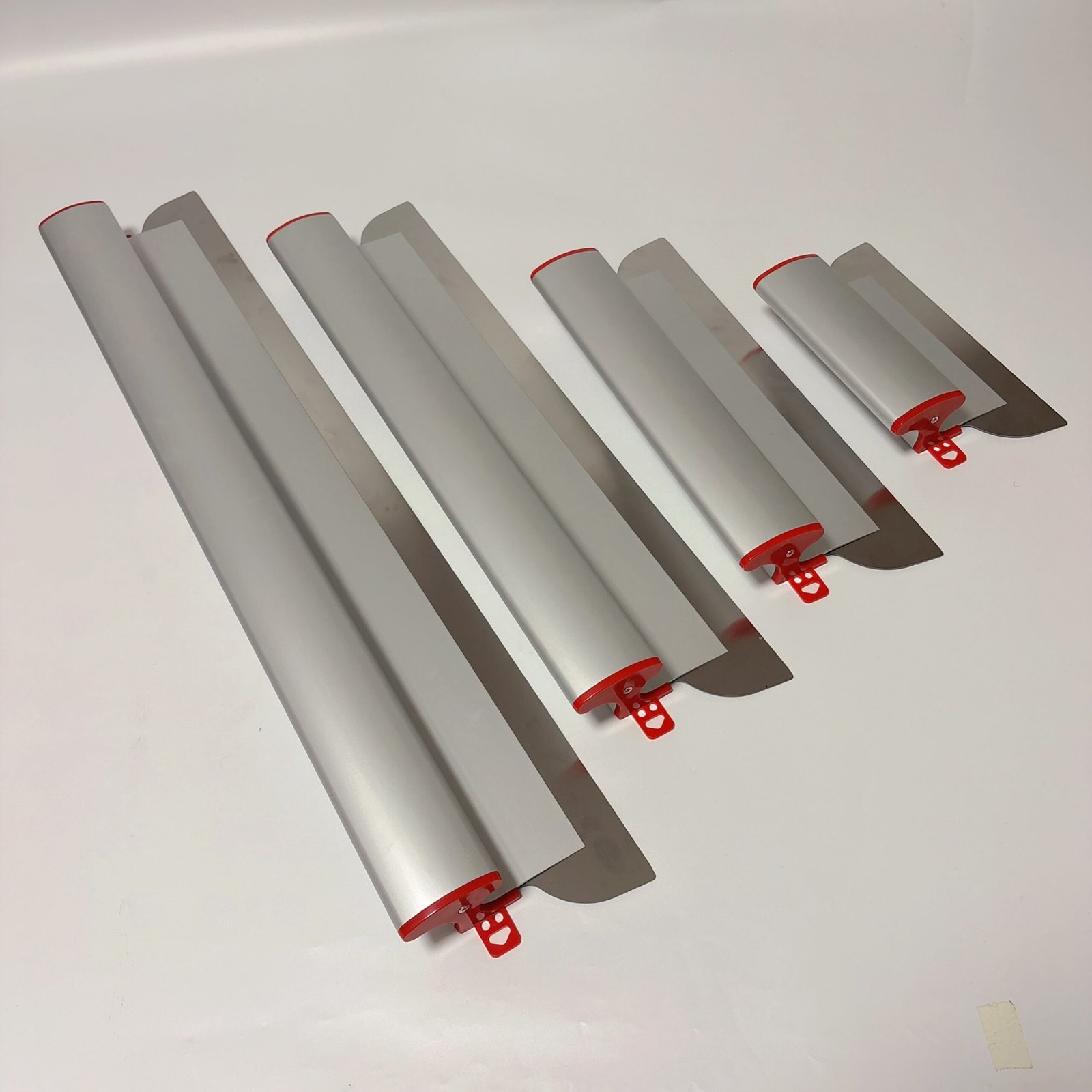

Wenn ein Haus renoviert und die Wände neu gestrichen werden müssen, ist der Abziehspachtel eines der wichtigsten Werkzeuge zum Verputzen. Er ist in verschiedenen Größen erhältlich und hilft Stuckateuren, die Spachtelarbeiten an allen Wänden schnell, gekonnt und mühelos zu erledigen. Doch wie wählt man einen hochwertigen Aluminium-Spachtel aus? Wir werden dies im Folgenden ausführlich erklären.

1. Wie man die Klinge auswählt

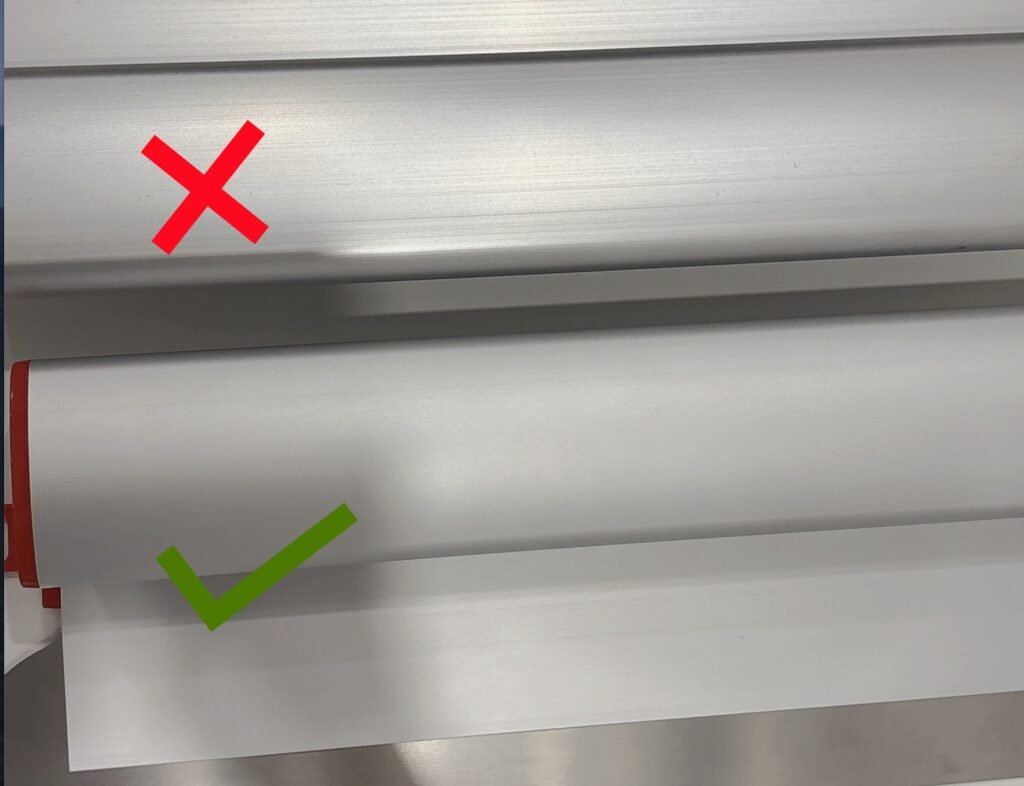

Die Klinge ist das Kernstück eines Schaumspatels. Sie besteht aus hochwertigem rostfreiem Stahl und hat in der Regel eine Stärke von 0,3-0,5 mm. Eine hochwertige Klinge hat eine gleichmäßige Dicke, liegt eng am Aluminiumgehäuse an und weist einen glatten Bogen an der abgeschrägten Kante auf.

2. Wie man das Gehäuse auswählt

Das gesamte Gehäuse eines Aluminiumspatels ist aus einer Aluminiumlegierung gefertigt. Hochwertige Abschöpfspatel werden einer Oberflächenbehandlung durch Aluminiumoxidation unterzogen, was zu einer gleichmäßigen und einheitlichen Farbe ohne Kratzer oder Linien führt.

3. Vergleich der Klingenbefestigungsmethoden

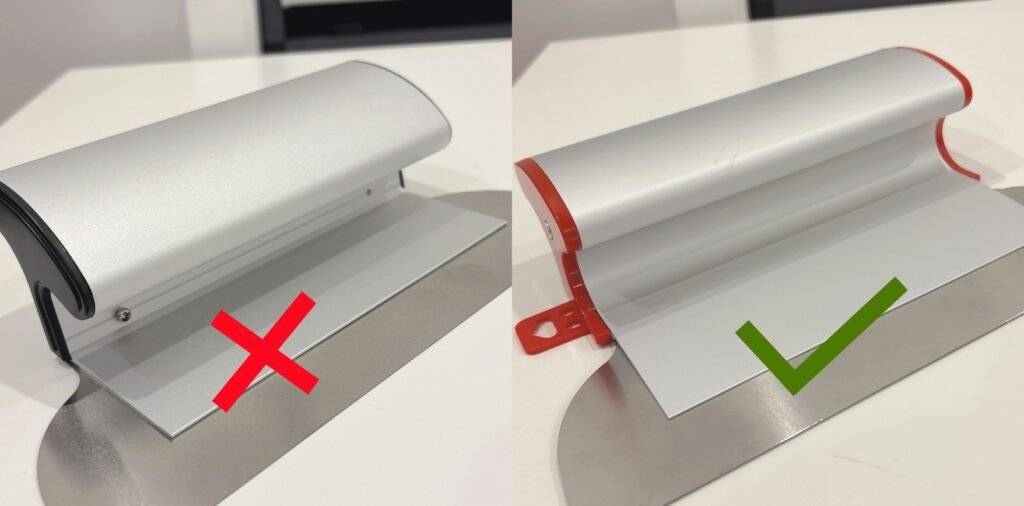

Viele auf dem Markt befindliche Aluminiumspachtel verwenden nur wenige Schrauben, um die Klinge im Gehäuse zu befestigen. Während des Gebrauchs besteht dadurch die Gefahr, dass die Klinge abfällt oder bricht. Das neue Aluminium-Spachtelwerkzeug von Amaltool verzichtet auf diese Konstruktion und verwendet eine Klingenbefestigung, die den europäischen und amerikanischen Normen entspricht und eine sichere und zuverlässige Verwendung gewährleistet.

4. Welche Methode des Klingenwechsels ist besser?

Bei herkömmlichen Aluminiumspateln muss zum Auswechseln der Klinge die gesamte Endkappe entfernt werden, was dazu führen kann, dass sich die Endkappe löst. Der neue Aluminium-Abschäumer von Amaltool verfügt über ein geniales Schiebeplattendesign, das die Demontage der gesamten Endkappe überflüssig macht. Schieben Sie die Platte einfach auf, um die Klinge leicht zu ersetzen.